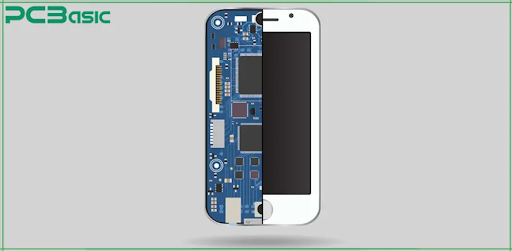

In the world of modern electronics, smartphones represent some of the most complex and compact devices ever made. At the heart of every smartphone lies its circuit board—an intricate layout of micro-components that manage everything from touchscreen responsiveness to wireless communication. But these circuit boards are not just raw materials; they are brought to life through PCBA (Printed Circuit Board Assembly). And the quality of this assembly process is critical.

What Is PCBA?

PCBA refers to the complete process of soldering and assembling components onto a bare PCB (Printed Circuit Board). This includes surface-mount technology (SMT), through-hole insertion, reflow soldering, and various inspection and testing stages. The goal is to turn a static PCB into a functional and reliable electronic control center.

How PCBA Affects Phone Circuit Boards

Smartphone circuit boards are extremely compact and densely populated with micro-scale components. Here’s why high-quality PCBA is essential:

1. Reliability and Longevity

Poor solder joints or misaligned components can cause intermittent faults or complete failure. High-quality PCBA ensures strong electrical connections and mechanical stability, increasing the overall lifespan of your phone.

2. Signal Integrity and Performance

In smartphones, even minor electrical noise or interference can affect performance. Proper component placement and precision soldering preserve signal integrity—crucial for fast processors, accurate sensors, and clear audio.

3. Compact Design Compatibility

Phones demand miniaturized assemblies with 0201 or even smaller components. Only precise, high-quality PCBA processes can handle such tight tolerances without compromising functionality.

4. Thermal Management

Efficient heat dissipation is vital in mobile devices. A well-executed PCBA includes optimized thermal paths and component layout to prevent overheating and maintain device safety.

5. Compliance with Industry Standards

Smartphone manufacturers must meet strict certifications like ISO 9001, IPC-A-610, or RoHS. High-quality PCBA processes ensure compliance, reducing the risk of regulatory or customer returns.

Quality Control in PCBA: What to Look For

To guarantee performance in phone circuit boards, top-tier PCBA suppliers implement rigorous quality assurance methods, including:

- Automated Optical Inspection (AOI)

- X-ray inspection for hidden solder joints

- In-circuit testing (ICT) and functional testing

- Cleanroom assembly to avoid contamination

- Traceability systems for defect analysis and process control

Conclusion

Your smartphone’s seamless performance relies on more than just its chipset or display—it depends on the quality of PCBA that builds its circuit board. From ensuring stability and efficiency to supporting advanced features, a high-quality PCBA process is the foundation of reliable phone hardware.

When choosing a PCBA partner for mobile electronics, insist on proven quality systems, precise process control, and experience in high-density assembly. After all, every feature in your phone—camera clarity, fast charging, or app speed—starts with a properly assembled circuit board.